Selection of drum diameter and thickness calculati

01st February 2023

The drum in the drum conveyor is a cylindrical part, divided into drive and driven rollers. It is widely used in rotary screen printing machines, digital printers, conveyors and paper making. The drum in the drum conveyor is usually made of seamless steel pipe, or according to the needs of different processes, such as aluminum alloy 6061T5304L/316 stainless steel, 2205 duplex stainless steel, the same steel casting, solid forged alloy steel core.

After roller forming, for the needs of rust prevention, corrosion prevention, wear resistance and support, surface treatment or coating such as painting, galvanizing, TEFLON coating, rubber coating, chrome plating, ceramic coating and oxidation are also required. Classified according to size, there are large rollers such as paper machines (with a length of more than 10 meters and a diameter of more than 1500M), and small ones such as flat idlers used on belt conveyors on automatic assembly lines (generally less than 1 meter long), with a diameter of 159MM.

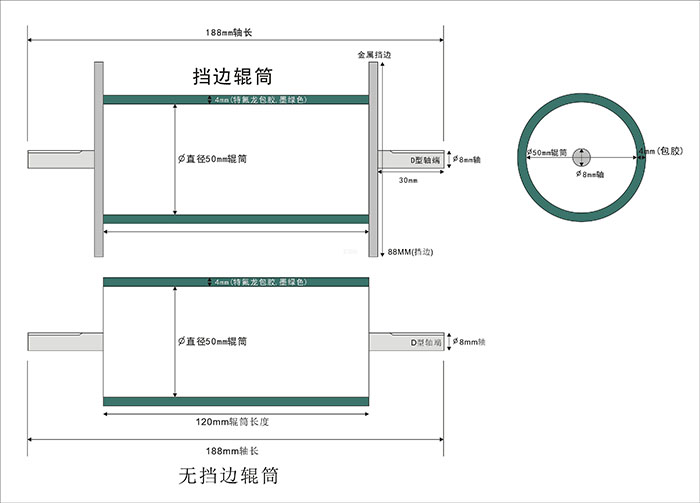

Roller diameter selection: 25mm, 32mm, 38mm, 42mm, 50mm, 57mm, 60mm, 76mm, 80mm, 89mm. The principle of determining the drum diameter is that when the tensile stress of the circular conveyor belt is large, the additional bending stress should be smaller; On the contrary, when the tensile stress is small, a slightly larger bending stress is allowed, and a smaller drum diameter can be selected.

Material selection of drum: carbon steel galvanizing, steel carbon chrome plating, carbon steel rubber coating, aluminum alloy, stainless steel, ABS, etc. Roller type selection: unpowered roller, single-chain roller, double-chain roller, "0" belt roller, tapered roller, trough roller. Fixing method of roller: spring pressed type, internal tooth shaft type, full flat tenon type and through pin hole type.

The production of roller is mainly composed of roller body initial turning, initial static balancing, shaft head interference device welding, fine turning and fine dynamic balancing. If the behavior tolerance such as roundness, cylindricity and straightness are required to be less than 0.2MM, the cylindrical grinder or roller grinder shall be used for grinding after finishing. If the surface hardness is required, the heat treatment process shall be added.

When conveying materials, the roller conveyor can also adjust the height of mechanical outriggers according to the needs of the table to cooperate with the production of other mechanical equipment. The thickness of the drum shell depends on the diameter of the drum, the length of the cylinder, the tension of the transport belt, the wear during braking and other factors. It is very difficult to calculate the thickness of the drum shell, and the calculated value is generally small. In addition, considering the wear resistance and ease of manufacturing, the thickness of the drum shell is generally taken as thicker. After determining the thickness of the drum shell, the strength of the drum shell is checked. Since the shell is subject to normal and tangential loads, Moreover, the load varies along the circumference of the drum. At present, there is no accurate calculation method for the calculation of the shell. Although the finite element calculation can give relatively accurate results, due to the lack of a special general program for the calculation of the belt conveyor drum, only the finite element analysis can be carried out on individual drums. The maximum stress of the shell in the soft web is generally generated in the middle of the shell length and the outside of the shell thickness, Generally, the stress can be expressed by an approximate value with sufficient accuracy.