Changsha Hazardous Waste Disposal Center was offic

18th November 2022

The production of hazardous waste in China is increasing, and the output of hazardous waste in 2018 has reached 118 million tons. In order to deal with the increasingly serious problem of hazardous waste, Changsha Hazardous Waste Disposal Center was completed and officially put into use.

The project is designed and installed by SREDER, mainly aimed at crushing and burning of ton barrels, 200L iron barrels or plastic barrels (empty barrels or containing semi-solid and solid materials, sludge, resin, paint residue, drugs, packaging bags, woven bags, waste cloth and other bulk hazardous wastes). 8-10 tons of hazardous waste will be treated every hour to fully meet the local demand for hazardous waste treatment.

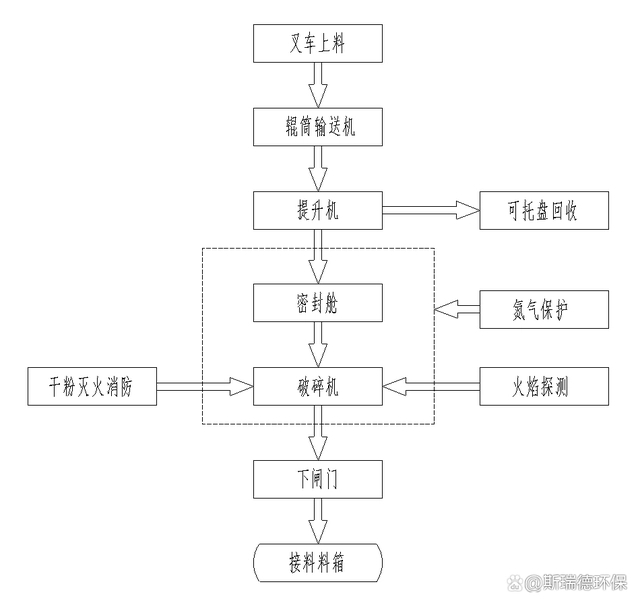

Process Flow of Changsha Hazardous Waste Disposal Center

Changsha Hazardous Waste Disposal Center has realized the intelligent automation of the whole system. The materials to be treated are first transported to the car at the bottom of the vertical elevator through the horizontal roller conveyor, then lifted vertically to the feeding height, and then sent to the feed sealing chamber of the crusher through the outlet roller conveyor.

After nitrogen is filled in the sealing chamber, the materials enter the crushing area. After crushing, the sealing ram at the bottom of the chute is opened. The crushed materials enter the receiving box, which is filled with materials and then transferred to the pit. At the same time, a new "lifting crushing" cycle begins.

Four Advantages of Changsha Hazardous Waste Disposal Center

In the aspect of hazardous waste resource treatment, the pretreatment of hazardous waste is a key link. In the design of Changsha Hazardous Waste Disposal Center, SRED introduced European hazardous waste pretreatment technology, and improved it according to project experience and domestic conditions. Compared with general hazardous waste treatment system, Changsha Project has the following advantages:

The pallet is recyclable, effectively saving costs

The feeding turnover roller conveyor in the sealed cabin is designed with a lifting mechanism, and the tray recycling or non recycling mode can be selected according to the actual situation. The valuable standard pallets can be recycled and reused to help customers save costs and improve efficiency.

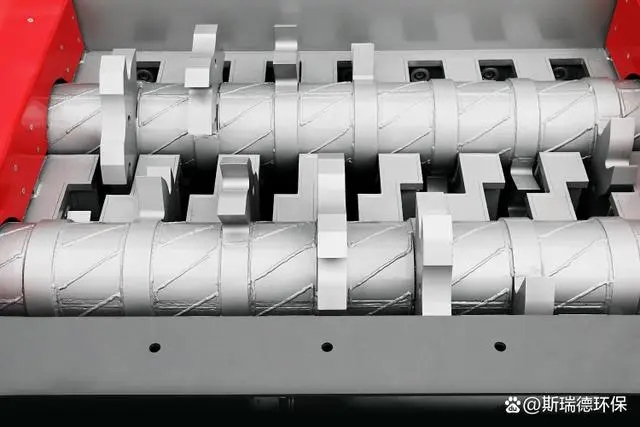

Coarse crusher configuration, strong crushing effect

A large hydraulic direct drive coarse crusher is adopted, with a rotating shaft speed of 0-40r/min, multiple crushing mechanisms such as shearing, chopping, tearing and extrusion, and a relatively uniform material flow output. Most of the size is controlled below 400mm, which makes it easy to be competent for crushing mixed solid wastes with complex components.

Nitrogen protection system+dry powder fire protection system, high safety

The nitrogen protection system is equipped to effectively avoid the burning of materials due to impact when entering the crushing bin. The nitrogen analyzer monitors the internal nitrogen amount online, and replenishes nitrogen in time to replace oxygen, which plays a protective role in the whole crushing process. In addition, the system is also equipped with a dry powder fire protection system. The flame detector detects the crushing bin, discharge bin and other spaces prone to fire on line. If a fire occurs, the system will automatically alarm and start the dry powder fire extinguishing device.

Intelligent control system, high degree of automation

The successful operation of Changsha Hazardous Waste Disposal Center has realized the safe control and stable operation of hazardous waste from feeding to crushing, and demonstrated the professional ability and competitive advantage of SRED in solid waste crushing equipment and resource-based one-stop solution. In the future, we will continue to focus on technology R&D and innovation, and provide customers with more professional and efficient one-stop service for solid waste treatment!